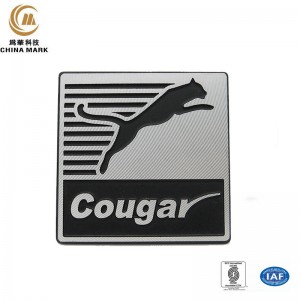

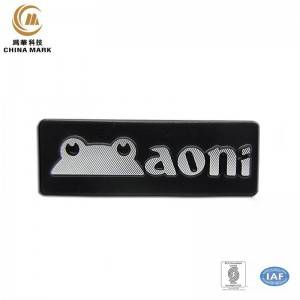

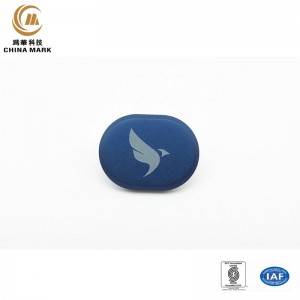

Manifattur tal-pjan?i tal-isem, Badge tal-Cartoon | WEIHUA

Jekk inti interessat li tag?mel kuntatt ma 'rappre?entant tal-bejg? tag?na ikklikkja hawn

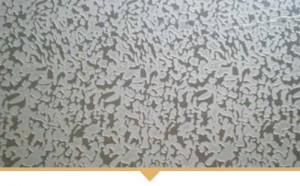

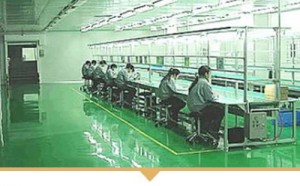

Il-pro?ess ewlieni juri kif jidher hawn ta?t

Pass 1: St. pjan?a

Pass 2: Qtug? bil-lej?er skont id-dwg tal-in?inerija

Stadju 3: Film jew kisi fil-?anut ming?ajr trab, imma?ni ta 'espo?izzjoni g?ad-dawl

Pass 4: In?i?joni, ji?ifieri, ne??i materjal permezz ta 'reazzjoni kimika jew korru?joni fi?ika

Pass 7: Forn tal-industrija, temperatura g?olja, temperatura baxxa u temperatura kostanti.

Pass 5: Ikseb iktar approfondit billi tiskatta darba, u temm in-nis?a billi ttellg?u darbtejn, b?all-qam? tas-sil?.

Pass 8: Spetturi professjonali u ?addiema fl-imballa??

Pass 6: Mag?mul fil-?anut ming?ajr trab, minn ?addiema professjonali u tag?mir avvanzat

Pass 9: Applikat b?ala partijiet mnaqqxa bi pre?i?joni g?all-komponenti rqaq elettroni?i g?all-industrija tal-avjazzjoni, makkinarju u industrija kimika

Ikteb il-messa?? tieg?ek hawn u ibag?tilna