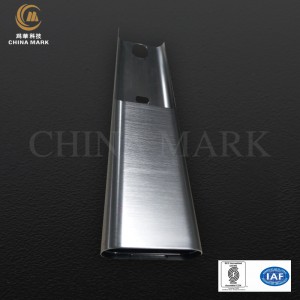

20 mau makahiki o ka ?ike i ke kau anuanu / kaha ki?i / ?ohana forging ?oihana o ke kinikini aluminika, e kia ana i ka wehe ?ana a me ke ku?i ?ana / kaha ki?i ?ana / forging / hana ?ana o CNC a me ka hana ?ana i nā huahana alumini, puna puna extrusion.

?O ka extrusion alumini no ka ?epekema a me ?enehana ?o Kina, ho?ohana ākea, nā papa inoa piha, maika?i maika?i, lawelawe papa mua, hiki ke ho?onohonoho pono ?ia ka extrusion aluminium e like me nā makemake ?oko?a, ?olu?olu e kūkākūkā;

?Ke ka?ina hana extrusion alumini extrusion

?I. nā ka?ina hana:

1. Ho?omehana i ka paukū ingot i 380 ℃ - 420 ℃ i ke ?ano o ka gradient ho?omehana o 100 ℃ / 1 hola.

2. Wahi a ka papa hana hana, koho i ka nui kūpono o ka ho?omehana umu ?aumā kūpono i 480 ℃ - 520 ℃, nā ?ikepili ?enehana kūikawā e like me ka wela o ke ka?ina hana i hō?ike ?ia.

3. Wahi a ka papa hana, koho i ka punahelu i kūlike me ka ho?olālā, e wela iā ia a 460 ℃ - 500 ℃, a e mahana no 2-4 mau hola.

4. Ho?omaka i ka mīkini ho?omaha extruder - ka?a ka?a.

5. Wahi a ke ka?ina ho?okahi o ka ho?olālā, koho i ka cushion kūikawā no ka ho?ohehe?e ?ia e ho?ouka ?ia i ke kumu puna, a laka i ke kumu mo?o i ke kūlana extrusion.

6. Laka i ka pahu pa?a a hāpai i ka pā alumini wela i ke kūlana kūpono o ka gallbladder material ma o ka ho?ohana ?ana i ka ?ānai hānai.

7. Haku paukū?oloka?a extrusion

8. E lohi ka wikiwiki wikiwiki, a pono e ho?oponopono i ka wikiwiki waena e like me ka maika?i o ka ?ikepili ma ka puka.

9. E ho?opa?a i ka helu mould, helu ?aukā aluminium, kaomi pu?ukū haku a ho?oku?u i ka wikiwiki i ke kiko?ī i ka mo?olelo kumu.

?Ii. Nā pono hana

1. ?O ka mahana o ke ko?oko?o alumini e ho?omehana ana ma ka mīkini: A make pālahalaha: 500 ℃ - 520 ℃ b. mahele make: 480 ℃ - 500 ℃ c. ho?okō ?ia nā hana ?enehana kūikawā e like me nā koi hana kūikawā.

2. Ke ka?ina hana ho?omehana punahelu: a. make pālahalaha: 460 ℃ - 480 ℃ b. mahele make: 460 ℃ - 500 ℃

3. Ke kau wela o ka ?ōmole: 380 ℃ - 420 ℃ ke anuanu o ka pi?ina ingot 280 ℃ - 360 ℃

4. Pono e loa?a ka ?ili i ka mea extruded, ?a?ohe mana?o lima no ka indentation longitudinal, maika?i a hiki i ka extruding palaoa, ?a?ohe kā?ei ?ōlinolino, laina ?ele?ele, mokulele mokulele ma waena o nā mokulele Yin a me Yang, ka huina o ka Angle, a he ki?eki?e ke ?oki ?ana. pae kiko?ī e like me ka pae ?āina.

5. Pu?e extrusion: ≤200㎏ / cm2

6 kaomi laka nui 120㎏ / cm2 - 150㎏ / cm2.

7. Mahana o ka aila waipuna ≤45 ℃

8. ?O ka wikiwiki o ka holo ?ana o ka ?ike kaohi pinepine ?ia i: 5 m / min --30 m / min

10. ?O kēlā me kēia extrusion o 80 mau ko?oko?o -100 ko?oko?o, pono e ho?ohana i ka cinder cinder cylindrical clean up to clean the bile.

?Ekolu. Nā mea e pono ai ka nānā

1. I ka wā extrusion, inā pili ka make, ?a?ole ?oi aku ka nui o ka manawa make ma mua o 5 kekona.

2. Ke kau nei i ka mould, e ho?olohe i ka palekana a pale i ka wili mai ka hemo ?ana a haki ka wāwae.

3. Ke ho?oku?u ?ia, kapu loa ?ia ka nānā ?ana i ka puka.

4. Ma mua o ke kau ?ana i ka make, pono e nānā i ke kūlana waena a pono e ho?opili i ka ko?oko?o extrusion. Pono e holo ho?okahi ka mīkini hō?a?o ho?ouka ?ole ma mua o ka ho?omaka ?ana o ka mīkini.

5. Inā pili ka mahana o ke ko?oko?o ana, punahelu a me ka ingot barela i nā koina.

6.3 - e nānā i ka maika?i o nā ko?oko?o 5 i ho?okahi manawa.

E hō?oia pinepine i ka mahana o ka aila.

8. Inā māka ?ia kēlā me kēia pā alumini me ka helu umu ahi a me ka helu hā?awi.

?

?